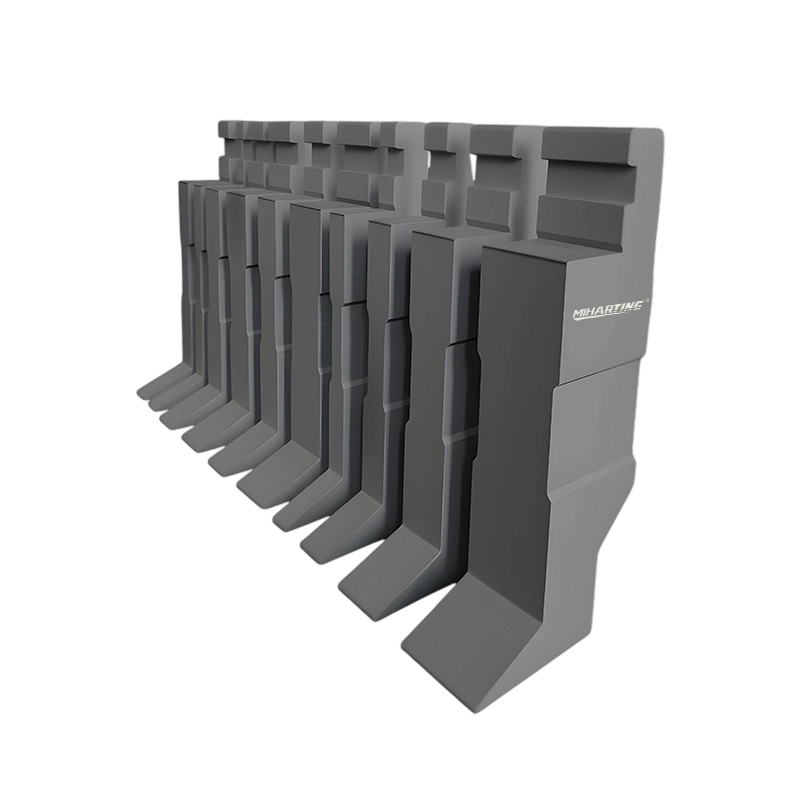

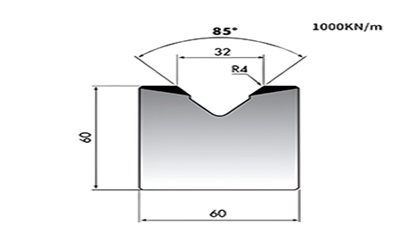

To select the correct bending die angle, first determine the desired bending angle based on the workpiece's design requirements. Then consider material properties, such as hardness and toughness. Hard materials require a slightly larger angle. Also, consider the bending process, as different processes have different requirements for angle accuracy. Also, evaluate the equipment's performance, as its pressure and stroke will influence angle selection. A comprehensive consideration of these factors should be used to determine the appropriate angle.

EN

EN