Quick clamps play an important role in clamping workpieces quickly and firmly in the bending machine. Quick clamps can quickly fix the workpiece on the workbench of the bending machine or between the molds to ensure that the workpiece will not move during the bending process.

This greatly improves the speed of loading. Compared with traditional clamping methods, quick clamps can complete the positioning and clamping of the workpiece in a short time, reducing auxiliary time and improving the overall working efficiency of the bending machine.

Additionally, die clamps for quick die change are essential for enhancing the efficiency of press brake operations. These clamps allow for rapid and secure changing of dies, minimizing downtime and maximizing productivity. By enabling quick die changes, these clamps contribute significantly to reducing setup times and increasing the overall throughput of the bending machine. For those looking to optimize their press brake operations, investing in the right press brake accessories, such as quick die change clamps, is crucial for achieving higher efficiency and improved performance.

Double-sided quick clamping can complete the clamping action of the workpiece in a very short time. Compared with the traditional clamping device, it reduces the unnecessary operation steps and time consumption in the clamping process through the optimized mechanical structure design.

Its unique double-sided design allows for simultaneous clamping of workpieces of varying orientations and shapes. This flexibility eliminates the need for frequent fixture changes when processing different workpiece types.

High and uniform clamping force: Double-sided quick clamps provide a high clamping force, ensuring that workpieces do not shift during the bending process.

Additionally, die clamps for quick die change are essential for enhancing the efficiency of press brake operations. These clamps allow for rapid and secure changing of dies, minimizing downtime and maximizing productivity. By enabling quick die changes, these clamps contribute significantly to reducing setup times and increasing the overall throughput of the bending machine.

Precise Bending Accuracy: The three-point bending machine mold utilizes a unique three-point support structure to more precisely control the stress points and deformation of the sheet metal during the bending process.

Wide Applicability: The mold can process a variety of sheet materials and thicknesses. The mold can adjust the distance and pressure between the three points to achieve optimal adaptability for sheet metal of varying thicknesses, eliminating the need for frequent mold changes and significantly improving production efficiency.

Extend the service life of the mold: The three-point bending machine mold distributes the pressure evenly on three supporting points, reducing the pressure peak on the local part of the mold and reducing the wear rate of the mold, thereby significantly extending the service life of the mold and reducing the frequency of mold replacement.

The push-button quick clamping system on the press brake achieves rapid clamping, significantly reducing the time required to clamp the workpiece compared to traditional clamping methods and significantly improving production efficiency.

It reduces errors caused by unskilled operation and reduces worker workload, making long-term work more manageable.

Secure clamping ensures bending accuracy, ensuring workpieces meet dimensional and quality requirements, reducing defective products and improving overall product quality.

This quick clamp accommodates a wide variety of workpiece sizes and shapes, making it suitable for diverse bending production tasks. This enhances the press brake's adaptability to diverse production needs and expands the equipment's application range.

The Amada quick clamp features an efficient clamping mechanism, enabling quick workpiece clamping.

The quick clamp enables highly precise workpiece positioning. Its design ensures that workpieces are accurately positioned during clamping, achieving micron-level positioning accuracy.

Amada quick clamps can adapt to a variety of workpiece types and sizes. Whether it is a small precision part or a large structural part, it can be clamped by adjusting the relevant parameters of the quick clamp or replacing some accessories. This wide compatibility allows companies to process different products without frequently changing clamping equipment, reducing production costs.

The dies can be quickly locked and released for various upper dies.

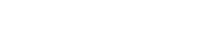

Compatible with Wila standard upper dies, the dies feature a monolithic structure with a built-in, custom expansion tube and an aluminum alloy faceplate and scale.

The dies can be quickly locked and released for various upper dies.

Compatible with Bystronic standard upper dies and featuring a custom-designed segmented hydraulic cylinder connection structure, this design offers high pressure and is suitable for large-tonnage press brakes.

The dies can be quickly locked and released for various upper dies.

Applicable to European standard upper mold, simple structure and easy operation.

The pump station is suitable for upper die hydraulic quick clamping and hydraulic quick clamping with integrated embossing worktables.

Figure 1 shows a single-output pump station, suitable for use with either the upper die hydraulic quick clamping or the hydraulic quick clamping with integrated embossing worktable.

Figure 2 shows a dual-output pump station, suitable for use with both the upper die hydraulic quick clamping and the hydraulic quick clamping with integrated embossing worktable.

The pump station is equipped with a high-precision intelligent digital pressure controller, which allows for adjustable operating pressure ranges. It automatically replenishes pressure below the lower limit and automatically stops pressurizing above the upper limit.

To use the quick clamp of the bending machine to work efficiently, you can follow the following steps:

A. Preparation

1. Check the equipment: Carefully check the overall appearance of the bending machine to ensure that the machine body has no obvious damage or deformation. Check the mechanical structure of the quick clamp, such as whether the clamping claws, connecting rods and other parts are worn or loose.

2. Material preparation: According to the requirements of the bending workpiece, select the appropriate plate, check that the surface of the plate should be flat, without rust, cracks and other defects. Measure the thickness, width and other dimensions of the plate to ensure that it meets the processing requirements.

3. Mold installation: Select an appropriate press brake tooling and check whether the mold is installed vertically and aligned.

B. Quick clamp installation and debugging

1. Install the quick clamp: During the installation process, ensure that the installation base of the quick clamp fits tightly with the bending machine workbench, and lock it firmly with bolts or other fixing methods to prevent the quick clamp from shifting during operation.

2. Debug the quick clamp: Start the control system of the bending machine and the power source of the quick clamp. Use the control buttons on the operation panel to debug the clamping and loosening actions of the quick clamp.

C. Bending operation

After confirming that the plate is firmly clamped and the parameter settings are correct, press the start button, the slider of the bending machine starts to move downward, driving the upper die to bend the plate.

D. Subsequent work

Cleaning and maintenance: After the work is completed, turn off the power source of the bending machine and the quick clamp, and clean the plate debris, oil stains and other debris on the workbench. Clean the quick clamp and wipe the oil and dust on the surface of the clamping claws, connecting rods and other parts.

1. Fix the workpiece.

2. Improve production efficiency, thereby reducing production costs and increasing the economic benefits of the enterprise.

3. Ensure product quality, ensure the quality consistency of bent parts, and enhance the competitiveness of enterprises in the market.

4. Expand the processing range, be able to handle more types of workpieces, and meet the needs of different customers.

5. Easy to operate.

1. Fast clamping

2. Accurate positioning, reducing the defective rate.

3. Strong adaptability

4. Safe and reliable