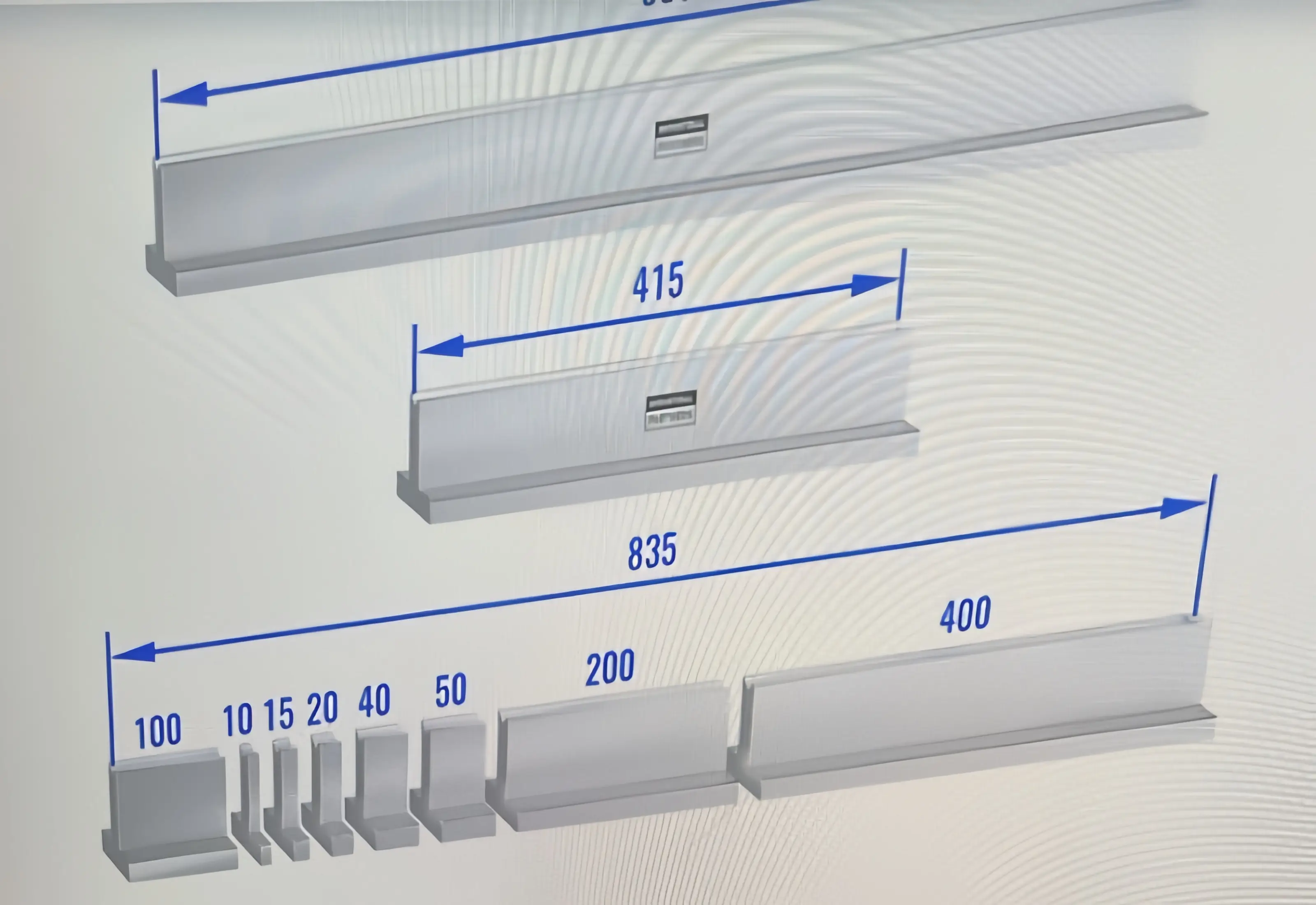

Generally, we design the corresponding drawings according to the customer's workpieces and use CAD/CAM technology to make customized bending machine molds to ensure the precision of the production process.

We generally use wear-resistant raw material 42Cr, and then forge the material.

Rough milling of materials, milling of blanks into smooth materials.

Treat the smooth material with high temperature to eliminate the internal stress of the material.

The heat-treated material is ground with a grinder and fine-milled with a CNC milling machine.

Use CNC machining center to mill the cutting edge, V groove, corners and edges.

The finished mold should be calibrated horizontally and calibrated again after the finished product

After the mold is processed, it must be tested and installed to ensure the accuracy.

All custom press brake tools are laser marked with parameters to ensure that customers can find them accurately and quickly after receiving them.

The general delivery period of MIHARTING press brake tooling manufacturers is about 20 days, and the warranty period is 2 years.