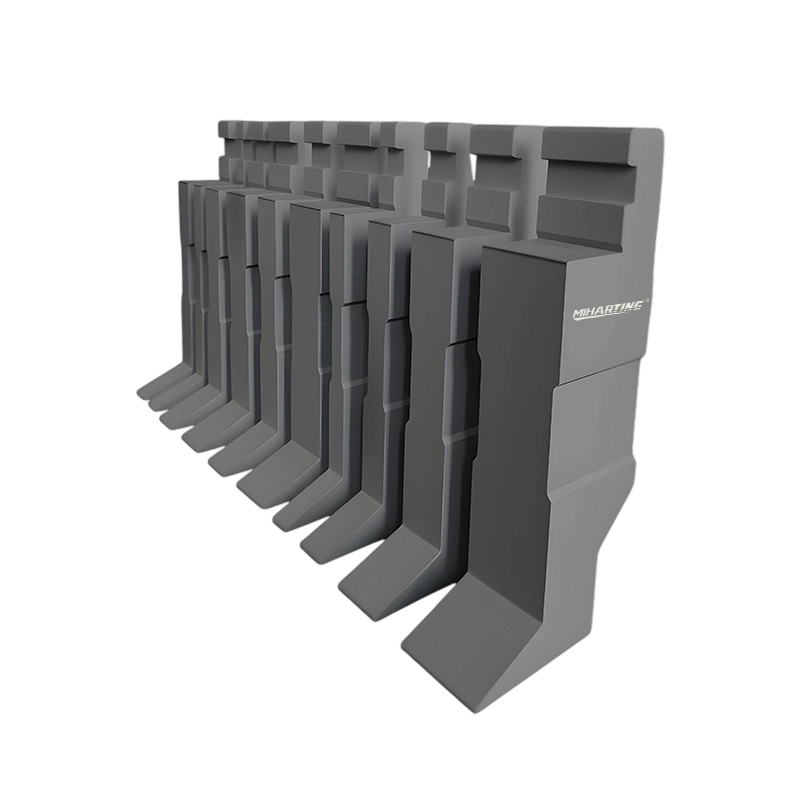

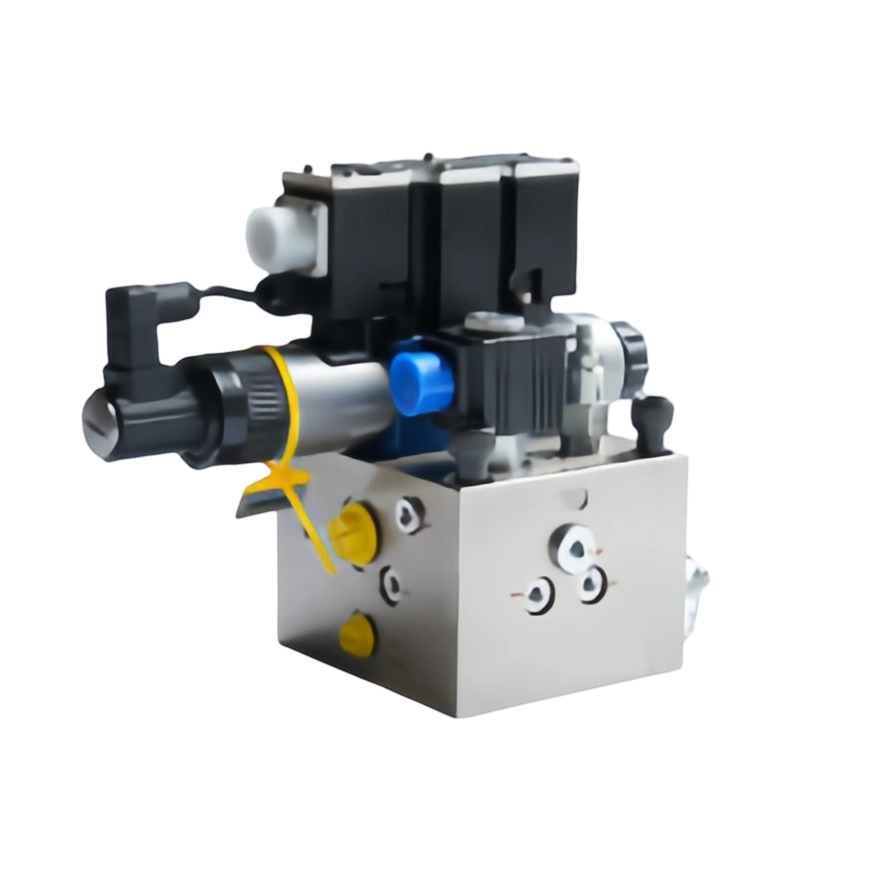

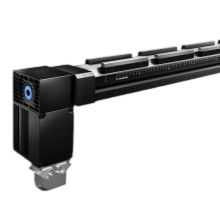

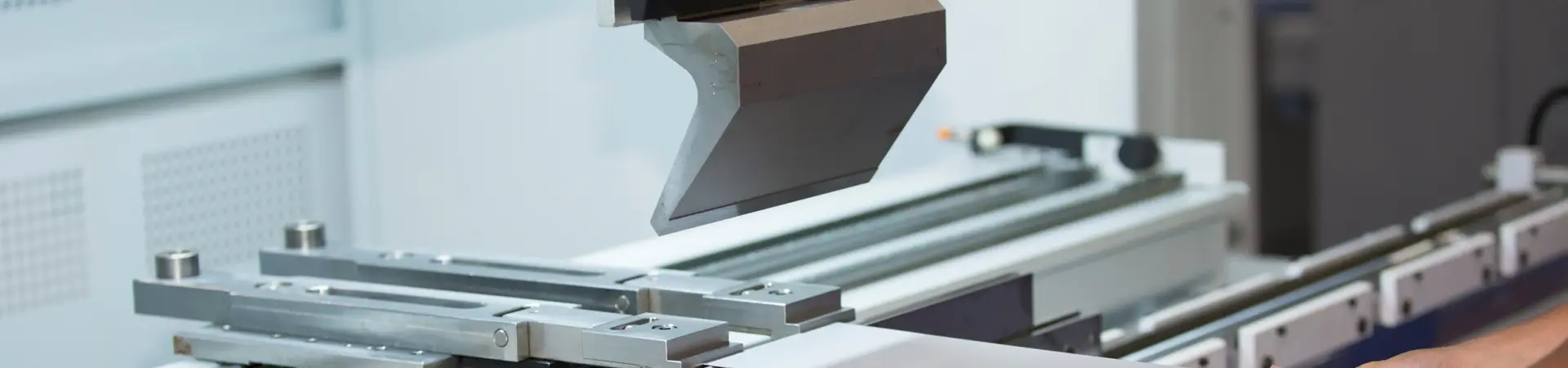

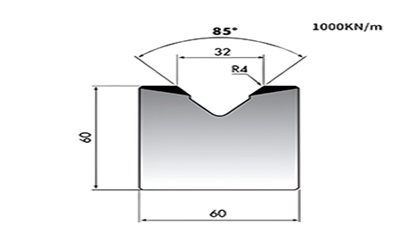

In addition to the press brake toolings, other related press brake accessories include bending machine system, quick clamp, motor, hydraulic valve, mechanical compensation, ball screw, etc. The toolings is used to form the workpiece, the punches and die cooperate to complete the bending action, the blade is used to cut the material. These accessories work together to ensure that the bending machine completes the metal processing task efficiently and accurately.

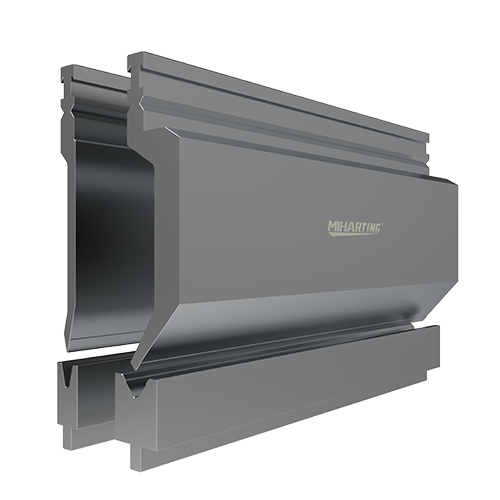

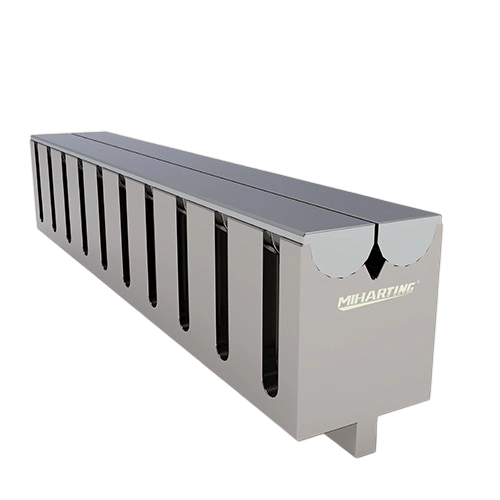

For specialized applications, a sheet metal box and pan brake can be an essential tool. This type of brake allows for precise bending and forming of sheet metal into boxes, pans, and other intricate shapes, complementing the capabilities of traditional press brake systems and enhancing overall production versatility. Press brake tool holders are also crucial components in the bending process. High-quality tool holders contribute to the overall precision and efficiency of the bending machine, making them indispensable for achieving optimal results.

EN

EN